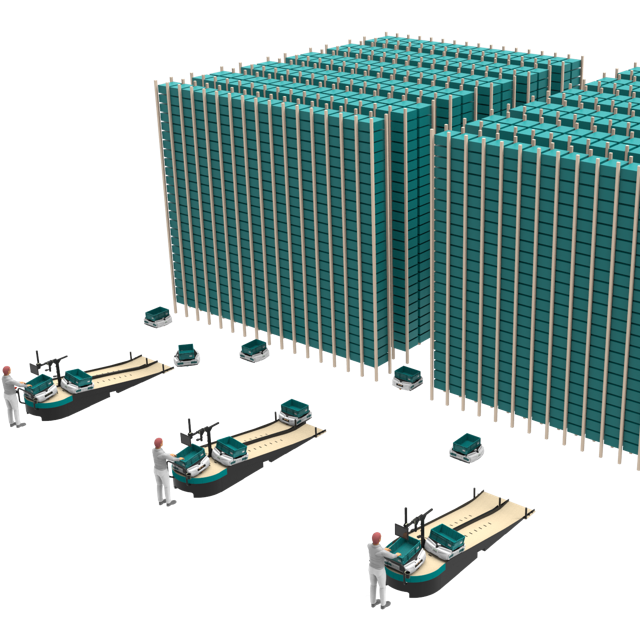

Shuttles are a type of Automatic Storage and Retrieval System (AS/RS) that deliver product via an autonomous Shuttle (or called a vehicle or bot) that runs on a rack structure to store and retrieve cases, totes or trays or pallets. This type of AS/RS is also called a Goods to Person (GTP or G2P) system. Instead of operators roaming aisles to find products, the products are brought directly to the operators.

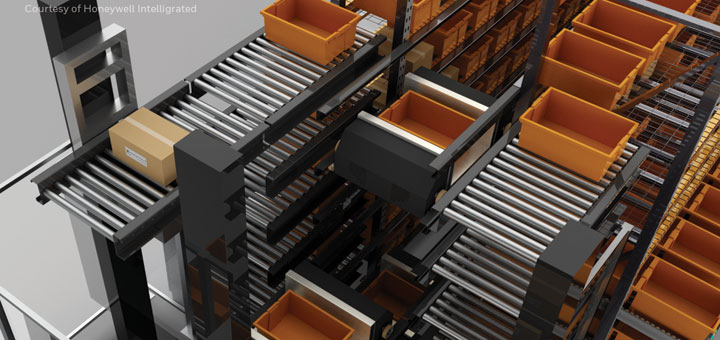

The shuttle vehicles, depending on the required system throughput, can be dedicated to a single level of the rack within an aisle or can move between multiple levels in an aisle using a vertical lift (or in some cases robots or elevators). Each vehicle has an extractor device capable of interacting with the product in the rack system in either a single, double, triple or quadruple deep scenario.

Because these bots are autonomous vehicles within the rack structure, the number of vehicles in a specific system can vary depending on the number of storage locations and the system throughput requirements and overall system size. Analyzing your data, business requirements help dictate which shuttle style, shuttle model and number of vehicles that are required to provide the best return on investment (ROI).

How does a shuttle system work? Wave of orders are optimized, then downloaded, and assigned to workstations. The shuttles are directed by the software and controls as to which item in the rack system to pick (or put away). The shuttle travels to the product and places the product onboard the shuttle. The shuttle then travels to the end of the aisle to deposit the product (or shuttle) on a high-speed lift. This lift brings the product (or shuttle) to the appropriate level to discharge onto conveyor (or AMRs) for downstream operations (i.e. order picking, route building, shipping, kitting, packing, etc.).

There are a wide variety of shuttle styles and models. This is where understanding an organizations data, order and inventory profiles, space restraints, labor sensitivity, business case and much more need to be scrutinized to determine the best (most efficient and cost-effective) solution. Utilizing a seven step RightFIT methodology will help assure success.

Shuttle technologies provide a high-throughput and cost-effective solution that uses less space than other systems and can grow with your business.

Need an Expert Opinion?

Why a Shuttle AS/RS is Right for Your Requirements

Goods-to-Person shuttle AS and /RS systems will provide the right engine to drive your facility’s performance:

- Handles multiple sized types of inventory

- Goods-to-Person (GTP or G2P) order fulfillment solution

- Route delivery and truck loading

- A case or tote sequencing system

- High speed tote/case buffer system

- Returns processing

- Kit building for manufacturing or line-side delivery

- Flow rack system auto-replenishment

- Traditional Shuttle

- Skypod AS/RS Shuttle

- Vertical Shuttle

- AMR Robot Shuttle

How Many Types of Shuttle AS/RS Systems Are There?

Conveyco utilizes its “power of choice” to provide a wide variety of shuttle AS/RS styles and models to meet every organization’s specific requirements of:

- Budget

- Throughput

- Labor

- Flexibility

- Inventory quantities

- Down-time

- Floor space availability

- Inventory characteristics

- Order profiles

Features of a Shuttle AS/RS:

A shuttle AS/RS system can provide many features that other storage and retrieval systems simply cannot.

- Improved inventory control (FIFO, LIFO, JIT)

- High throughput design

- Secure inventory

- Smaller system can be located on a mezzanine, second floor or low bay area of warehouse

- Lower energy consumption

- Improves space utilization

- Gentle product handling

- Labor reduction

- Flexible and scalable

Benefits of a Shuttle AS/RS System

Shuttle-based AS/RS systems can offer many operational, security and productivity benefit that other technologies simply cannot provide including:

- More efficient use of floor space

- Ability to reclaim unused vertical space

- Eliminates floor space requirements.

- Improves ergonomics and safety, resulting in fewer accidents

- Higher throughput capabilities

- Reduces labor costs

- Fewer labor constraints due to labor shortages

- Modular design for maximum flexibility

- Increases order picking accuracy

- Improves product security for premium inventory

Applications for a Shuttle AS/RS System

A Shuttle AS/RS can be used in a wide variety of applications while increasing operating efficiencies including:

- Goods-to-person order fulfillment solution

- Order assembly and route delivery/ truck loading

- A case or tote sequencing system

- High speed tote/case buffer system

- Returns processing

- Kit building for manufacturing or line-side delivery

- Flow rack system auto-replenishment

- Route delivery and truck loading

- A case or tote sequencing system

- High speed tote/case buffer system

- Returns processing

- Kit building for manufacturing or line-side delivery

- Flow rack system auto-replenishment

Why Conveyco Is the Best Solution Provider for Shuttle AS/RS Systems

Conveyco, as an independent systems integrator and can RightFIT the best shuttle technology for your organization’s needs and applications. We utilize the “power of choice” to analyze and source the best shuttle system for your exact needs. With over 40 years of experience, Conveyco has access to the vast majority of shuttle AS/RS systems on the planet. We analyze and determine the best solution for your specific requirements and then integrate the AS/RS technology into the overall system including the Warehouse Execution System (WES) software.

Specifications for Shuttle AS/RS Systems

- Load Description – totes, cases and trays – pallet handling models also available

- Load Size: (max.) 23” W x 47” L x 31” H

- Load Weight: 70-110 lbs.

- Throughput: 500 cycle/hr./aisle

- Height: Up to 60’ high system

- System Storage configuration: single, double, triple, and quadruple deep storage

*all specifications are nominal and subject to change without notice.

AS/RS Resources

Pallet Shuttle Systems: What They Are and What They Do

Lane Automotive Revs Up Order Fulfillment with High Performance Exotec Skypod