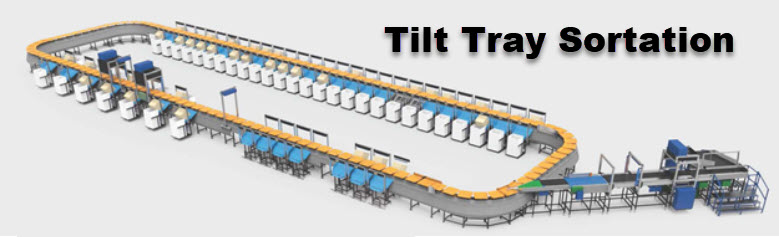

Tilt Tray Sortation Conveyor

The Tilt Tray Sorter is a highly reliable and effective sortation system. It can be configured as a loop or linear configuration depending on floor space availability and your application’s requirements. The Tilt Tray is comprised of a combination of tilting trays and chutes that deliver products to an assigned location.

The items or packages are either manually or automatically inducted onto the Tilt Tray Sorter based on orders that have been downloaded via software for picking. The products are scanned at induction and when the product reaches its assigned location the tray is tilted, and the product is discharged down the assigned chute. This can be done at a high rate of speed up to 50,000 items/hour.

Need an Expert Opinion?

Why Tilt Tray Sortation Conveyor Will Work for Your Operations

Tilt Tray Sorters provide high-speed sortation with gentle handling capabilities. This is ideal for a wide variety of product/SKU types and sizes including: apparel, boxes, cartons, pouches, bags, promotional material, documents, and fliers.

The Tilt Tray Sorter is available in two major configurations loop and linear. The loop configuration will provide the highest throughput and can act as two virtual sorters. By integrating two induction areas, one on each side of the loop, the sorter will act as two independent systems. Each will have induction, scanning, sortation and assigning dedicated chutes. The Loop Tilt Tray Sorter model will provide a sort rate that is nearly twice the carrier rate.

The linear (or over-under) configuration sorts from the upper level while the lower is used for the return (non-sort) level. This application works well in limited space and would be a direct replacement for a high-speed shoe sorter.

Features of Tilt Tray Sortation

One of the more flexible sortation solutions on the market today.

- Can handle a wide variety of product types, sizes, and weights.

- Longer items can be sorted using a double tray approach

- System design is modular and flexible to meet custom layout requirements

- High-speed sortation including running as virtual machine for peak performance during your busiest seasons

- Easy to maintain with very few moving parts and extremely high uptime characteristics

- The loop configuration allows for sort destination on the inside and outside of the loop

Benefits of Tilt Tray Sorter Conveyors

Tilt Tray sorters offers many unique characteristics that other high-speed sorters may not be able to achieve. For example, gentle handling of many product types at high-speed and high throughput.

- Gentle and accurate handling of a wide range of products

- A scalable and expandable technology

- Efficient energy consumption characteristics

- Complex chute design that allow for multiple order destinations per a divert location

- Proven technology with impressive uptimes and machine availability

- Simple maintenance

- It is ideal for a high number of sort locations and is designed for future expansion

- The noise level is much lower than other types of sortation systems

- Labor requirements are dramatically reduced

Applications for Tilt Tray Sorter Conveyors

The applications for Tilt Tray Sorter conveyor systems are vast. The common denominator is the requirement to have high-speed and reliable sortation with the flexibility to change as your requirements change. Some applications include:

- Direct to consumer DTC – batch pick order selection and sort to order

- Store returns & store replenishment

- Cross dock operation

- Kitting

- Mixed mail sorting

- Small and large parcel handling

- Poly bag handling

- Inbound sorting to put-away

- Apparel

- Medical & pharmaceutical

Options & Accessories for Tilt Tray Sortation Conveyor Systems

- Two sorters in one – A single tilt tray sorter in a loop can be configured with 2 induction and chute areas to double the carrier per hour rate.

- Automated, semi-automated or manual induction technology

- Pres-sort upstream of induction to allow for 2 virtual sorters

- Robotic or manual induction

Why Conveyco Is Your Best Choice for Tilt Tray Sortation Solutions

Conveyco, as an independent systems integrator, can RightFIT the best sortation technology to your application. We have the power of choice as we partner with several of the world leading Tilt Tray Sortation conveyor manufacturers. We apply your specific application requirements, business case and financial requirements to determine the best solution for your operations. We then integrate this best-of-class technology into your overall system including the Warehouse Execution System (WES) software.

Tilt Tray Sortation Conveyor Specifications

Order Fulfillment Resources

Choose the Best Sortation System for Your Application